Plastic media has transformed the treatment capability of trickling filters, making them 2-3 times more effective for a given volume. Reductions of more than 95% are now possible in BOD and ammonia, making trickling filters a viable option in many instances.

Trickling filters

Trickling Filters Australia can supply plastic media specific for the treatment solution. Media can be supplied as complete modules or flat packed for on-site assembly (welding). Our welding technology is environmentally friendly and does not use any solvents containing adhesives.

Features and benefits:

• Significantly increases the surface area for microbial film per unit volume

• Achieves void ratios >95%

• Avoids blockages deep within the profile

• Facilitates efficient oxygen delivery

• Resistant to rot, fungi, most dissolved chemicals and filter flies

• UV-stabilised

• 2-3 times more efficient than other media types

• Provides BOD and ammonia reductions up to 95%

Product Application Guide

| TRICKLING FILTER APPLICATION | WASTEWATER STRENGTH | MEDIA SELECTION | EFFLUENT QUALITY |

|---|---|---|---|

| BOD Roughing | High | Vertical Flow or Media Combination | 40-80% BOD Conversion |

| BOD Oxidisation | Medium | Cross Flow Media with Large and Medium Channels | 10-15mg/L |

| BOD & Nitrification | Low | Cross Flow Media with Medium Channel | BOD < 10mg/L NH2-N < 3mg/L |

| Nitrification | Extra Low | Cross Flow Media with Small or Medium Channels | 0.5-3 mg/L NG3-N |

Products

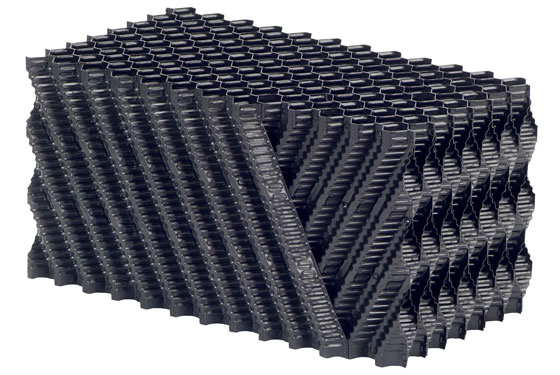

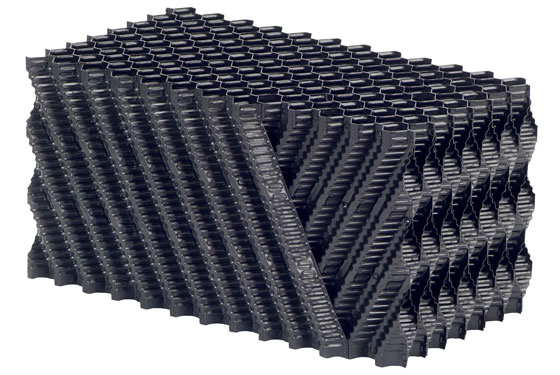

ENEXIO 2H BIODEK ® CROSSFLUTED MEDIA – HIGH EFFICIENCY – LOW EFFLUENT RATES

BIOdek® cross-fluted media (surfaces from 70 – 320 m2/ m3) provide reliable performance for biological sewage treatment processes. The different shapes of media allow for growing thin or thick biofilms depending on the process that is required.

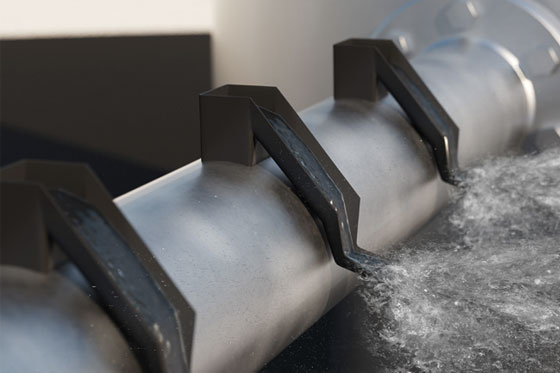

ENEXIO 2H BIODEK ® VERTICAL FLOW MEDIA – OPTIMUM SOLIDS DISCHARGE

Trickling filters and submerged fixed beds must have a balance between the new growth of biomass and the surplus sludge discharge. BIOdek® vertical flow media‘s tube channels enable the sludge discharge by water or air flushing. Their processes are best suited for higher organic loads with high growth of biomass.

PIERDEK® SUPPORT SYSTEM

The PIERdek support system is robust, durable and simple to install for all types of structured media trickling filters. The upright supports are adjustable to accommodate for all concrete base designs, ensuring an even platform for the media.

Rotating Distributors are designed to distribute wastewater evenly over trickling filter media to maximise the treatment outcome. Advancements in wastewater distribution using rotating distributors have contributed greatly in reducing the cost and maintenance involved with trickling filter systems. VA Teknik Rotating Distributors can be installed in both new and existing wastewater treatment tanks.

Trickling Filters Australia supply high quality and cost competitive hydraulic and motor driven rotating distributors from VA Teknik Sweden.

Features and benefits:

• Made to meet project specifications (i.e. Flow rate, SK value and wetting rates)

• Specially designed to prevent the ragging and blocking of the distributor arms

• Made from Stainless Steel -AISI304 with a design life greater than 20 years

• For high corrosion environments, distributors can be constructed using high grade steel (AISI316L) and duplex material.

• Excellent Life Cycle Cost (LCC) and low maintenance

• Does not require process or chemical engineering skills to operate.

Products

ROTATING DISTRIBUTOR

VA Teknik is a premium class manufacturer producing distributors with excellent performance which can handle high variation flow rates. Their rotating distributors can be used with all kinds of filter media.

Highly effective plastic media can be easily retrofitted into existing trickling filter infrastructure to replace old media. This is a cost efficient way to improve treatment efficiency without increasing energy usage and avoiding large capital upgrades.

Please contact us to enquire about upgrading your existing systems with plastic media trickling filters.

Random Packing

Learn more about our variety of random packing media used in trickling filters and MBBR (aeration and anoxic zones).

Additional products

Find out more about our extended range of wastewater treatment products and technologies.